Battery Energy Storage Systems (BESS) are becoming a critical enabler for electric and hybrid vessels, supporting emission reduction, fuel efficiency, and operational reliability. In marine applications, BESS architecture must meet far stricter safety, environmental, and performance requirements compared to land-based systems.

This article explains the architecture of Marine BESS, from individual battery cells to fully integrated onboard energy storage systems, with a focus on applications relevant to the Middle East.

Battery Cell Level

The foundation of any Marine BESS is the battery cell, where electrical energy is stored electrochemically. Lithium-ion cells are widely used due to their high energy density, efficiency, and cycle life.

For marine environments, cell selection is driven by:

- Thermal stability and safety characteristics

- Cycle life under partial and frequent charging

- Performance under high ambient temperatures

- Compliance with marine safety standards

Cell chemistry selection (such as LFP or NMC) plays a key role in balancing energy density, safety, and operational lifespan.

Module Level Architecture

Battery cells are assembled into modules, which provide mechanical structure, electrical connectivity, and localized monitoring. Modules are designed to ensure uniform temperature distribution and reliable electrical performance.

At module level, typical features include:

- Cell balancing and monitoring circuits

- Integrated temperature and voltage sensors

- Mechanical protection against vibration and shock

- Controlled thermal pathways for heat dissipation

Modular architecture allows easier maintenance, redundancy, and scalability — essential for marine operations.

Battery Rack and String Configuration

Modules are grouped into battery racks or strings, forming the primary energy storage blocks onboard a vessel. Marine BESS racks are designed to withstand harsh conditions such as humidity, salt exposure, and continuous vibration.

Key considerations at this level include:

- Electrical isolation and fault containment

- Redundant monitoring for safety-critical systems

- Structural design for ship motion and dynamic loads

- Optimized layout for space and weight constraints

The rack configuration defines system voltage and capacity, directly impacting propulsion and onboard power capabilities.

Battery Management System (BMS)

The Battery Management System is the core intelligence of Marine BESS architecture. It continuously monitors and controls the battery to ensure safe and efficient operation.

Core BMS functions include:

- Cell voltage and temperature monitoring

- State of charge (SoC) and state of health (SoH) estimation

- Protection against overcharge, over-discharge, and short circuits

- Fault detection and alarm management

Marine BESS typically use multi-layer BMS architecture (cell, module, and system level) to provide redundancy and compliance with classification requirements.

Thermal Management System

Thermal management is a critical design element in Marine BESS, especially in hot Middle Eastern climates. Effective cooling ensures battery performance, safety, and lifespan.

Common thermal management approaches include:

- Liquid cooling systems for uniform temperature control

- Redundant cooling loops for safety-critical vessels

- Integration with vessel HVAC or dedicated chillers

- Continuous temperature monitoring and fault response

Thermal design must consider both normal operation and emergency scenarios.

Power Conversion and Energy Management

Marine BESS does not operate in isolation. It interfaces with power conversion systems and the vessel’s Energy Management System (EMS).

This integration enables:

- Power sharing between batteries and generators

- Peak shaving during high propulsion demand

- Zero-emission operation during harbor maneuvering

- Optimized fuel consumption and reduced engine loading

The EMS coordinates battery usage based on operational mode, load demand, and safety priorities.

System Enclosure and Safety Architecture

Marine BESS systems are housed in dedicated enclosures designed to contain faults and protect the vessel. Safety architecture is layered and comprehensive.

Typical safety measures include:

- Fire detection and suppression systems

- Gas detection and ventilation control

- Physical segregation from critical ship systems

- Emergency shutdown and isolation mechanisms

Compliance with international marine standards and classification rules is mandatory at this level.

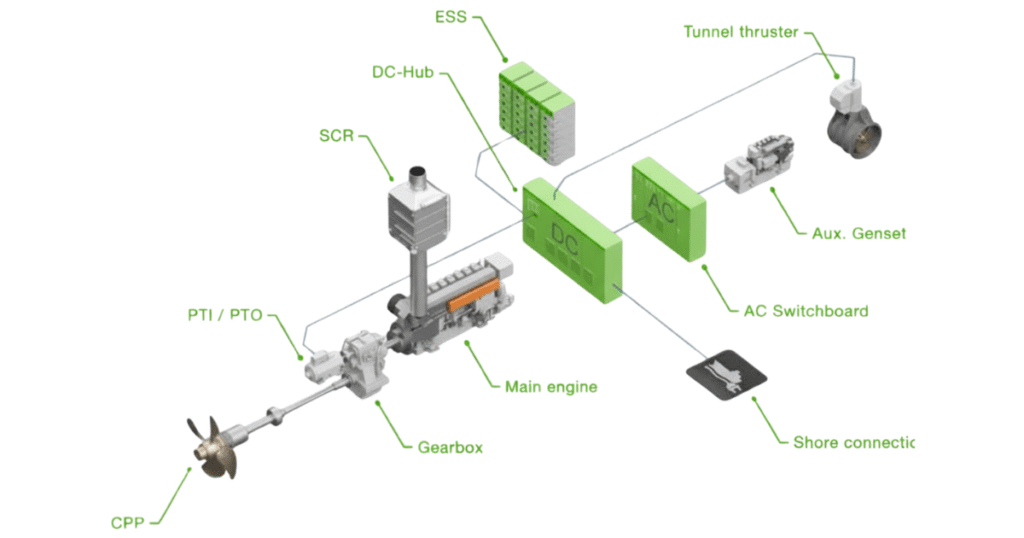

Integration with Vessel Systems

At system level, Marine BESS is fully integrated into the vessel’s electrical and control architecture. This includes interfaces with propulsion drives, auxiliary systems, navigation equipment, and monitoring platforms.

Successful integration ensures:

- Seamless transition between operating modes

- Redundancy and fail-safe operation

- Compliance with vessel automation systems

- Reliable performance under all operating conditions

Marine BESS in the Middle East Context

Marine BESS adoption in the Middle East is driven by:

- Port emission regulations and sustainability goals

- High fuel costs for harbor operations

- Demand for zero-emission and silent operation

- Harsh environmental conditions requiring robust design

Architectures must be engineered for high ambient temperatures, continuous operation, and long service life, making system design and partner selection critical.

Conclusion

Marine BESS architecture is a multi-layered system that combines battery technology, power electronics, control intelligence, and safety engineering. From cell selection to full system integration, every level plays a vital role in delivering safe, efficient, and reliable energy storage for modern vessels.

As marine electrification accelerates, well-engineered BESS architectures will be central to achieving sustainable and future-ready maritime operations.

If you are evaluating Marine BESS solutions or require technical support for ESS integration, feel free to contact Advandyn at [email protected] to discuss your project requirements.